Looking after pipelines can be a nightmare. Typically made of plastic or steel, and used to transport materials like oil, natural gas and hydrogen, they are generally very long indeed, and often located in all sorts of different terrain, some of it potentially very challenging, which can make them extremely difficult to access. They’re also sensitive pieces of infrastructure, requiring a lot of effort to keep them in good working condition, including regular, thorough inspections, as well as frequent cleaning and repair.

But it’s also work that is vitally important. Leaks have all sorts of potential negative consequences: precious resources are wasted, losing the pipeline owner money and possibly interrupting supply; technicians need to be deployed to fix them, which can be time-consuming and expensive; and, particularly in the case of a substance like oil, the environmental impact can be devastating.

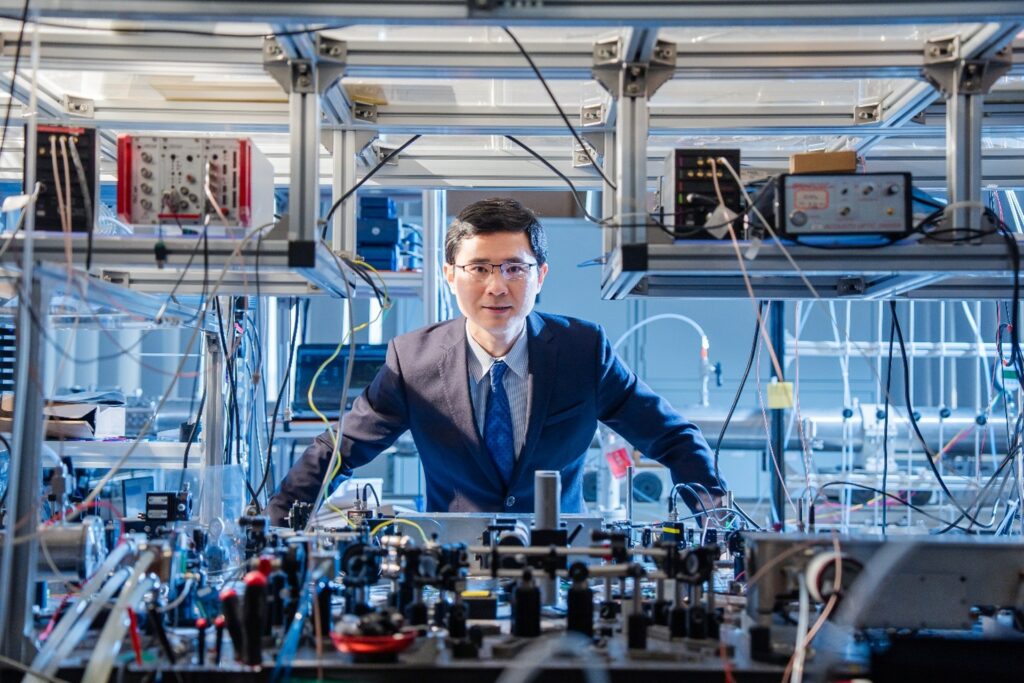

As a result, those industries have a pressing need for sensing systems that can monitor their pipelines, ensure everything is performing as it should and allow them to avoid costly leaks. Now, a CUHK research team led by Professor Ren Wei from the Department of Mechanical and Automation Engineering is riding to the rescue with a new series of intelligent gas analysers and detectors. Deploying a clever combination laser sensing and artificial intelligence technologies, they promise to usher in a sea change in the way in which this vital work is carried out.

The work of quality analysis, pipeline inspection and leakage detection has traditionally relied on laboratory equipment such as Gas Chromatography Mass Spectrometry (GC-MS). However, it’s expensive, bulky and can be extremely slow to use; it takes anything from tens of minutes to hours to analyse samples, requiring workers to first collect them and then haul them off to a laboratory to be tested. As a result, companies often deploy inexpensive devices like electrochemical sensors to do the job, but they’re not really up to the task: other parts of the atmosphere, such as water vapour, can easily interfere with them, hampering their accuracy and potentially resulting in false alarms. They also wear out very quickly – typically, in just a few months.

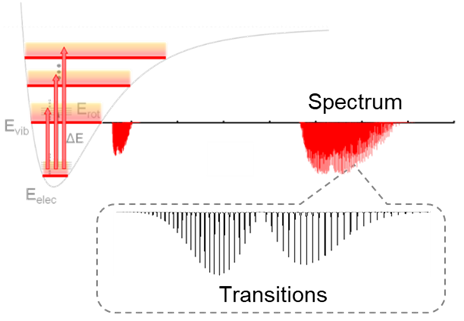

“Our laser-based sensing technology determines gas properties by analysing their specific spectral fingerprints,” says the leader of the new project, Professor Ren. “This approach offers a portable and cost-effective solution, enabling rapid analysis within milliseconds with high accuracy.”

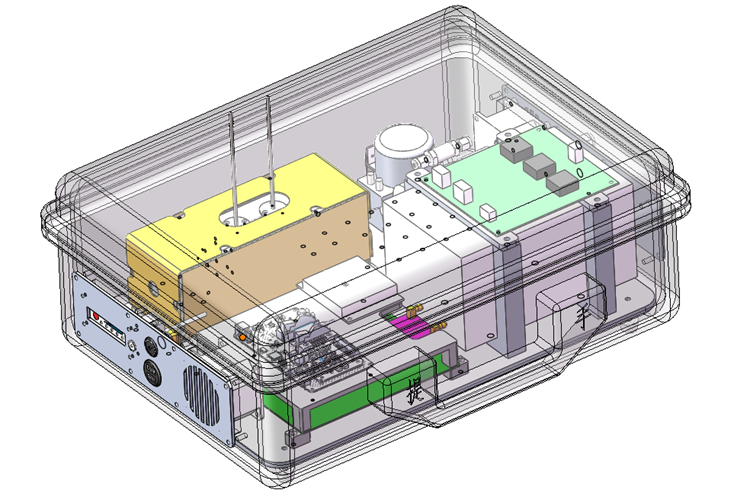

The new devices consist of three key components: a laser source that uses the specific absorption spectrum of the target molecule, a spectroscopic sensing module that boosts light-gas interaction and a photodetector that measures the amount of light passing through the gas.

“The use of a semiconductor laser minimises the system’s size, weight and power consumption,” says Professor Ren. “The optical cavity-based sensing module developed in our laboratory enhances detection sensitivity by over three orders of magnitude, compared to traditional optical methods. Recent advancements in artificial intelligence (AI) further improve data analysis, enabling more efficient and accurate measurements. Our technology facilitates fast, online analysis of multiple gas-phase species, further enhanced by deep learning algorithms.”

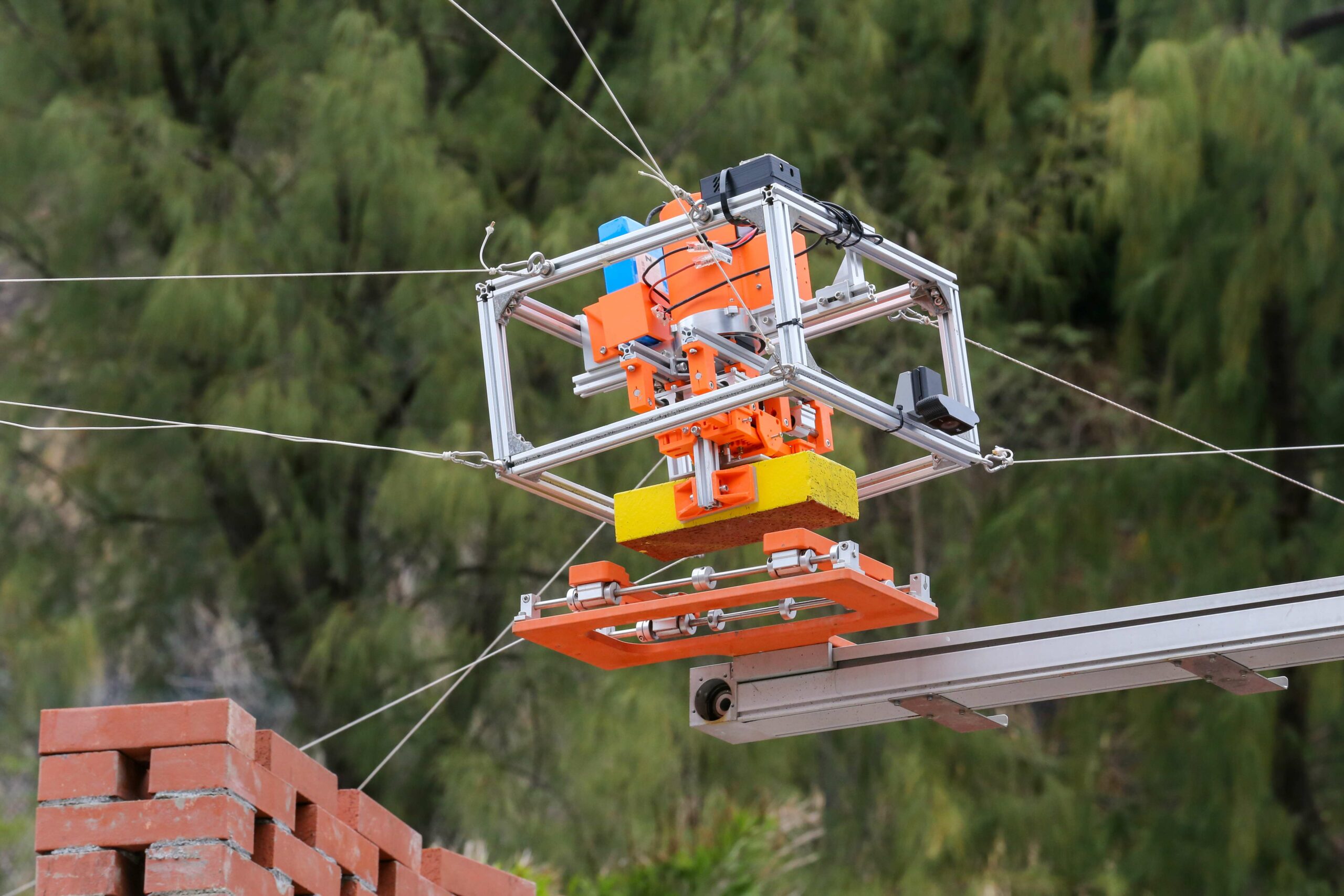

The new technology is set to be tested extensively in Hong Kong and mainland China, beginning in 2027. The team will pilot it at two or three oil and gas fields, in partnership with major oil, gas, pipeline and hydrogen companies, and will provide hydrogen sensors to commercial partners.

The research team has been focused on laser spectroscopy for over a decade. Their inventions allow gases to be detected down to the part-per-trillion level, while allowing for fast, broad chemical analysis. The team has already applied their inventions to flue gas monitoring in coal-fired power plants and energy systems and greenhouse gas quantification in environmental monitoring. They can even be deployed to analyse people’s breath, giving the technology potential uses in the non-invasive diagnostics of diseases.

In 2019, the team set up a company, LaSense Technology Limited, to commercialise its products – and with about 3.5 million kilometres of pipelines in place around the world, there’s a gigantic potential market for its new gas detectors. The company currently employs more than 30 people in Hong Kong and Shenzhen, but the latest development is set to see that grow, as it ramps up its efforts to transform an ingenious invention into a lucrative business.

“We have successfully commercialised laser-based gas analysers for greenhouse gas monitoring in the environmental sector,” says Professor Ren. “We expect our product line for the energy sector to be ready for market launch by the end of 2026. In addition to strengthening our R&D team, we plan to expand our marketing and sales efforts to significantly penetrate the market and increase our share.”