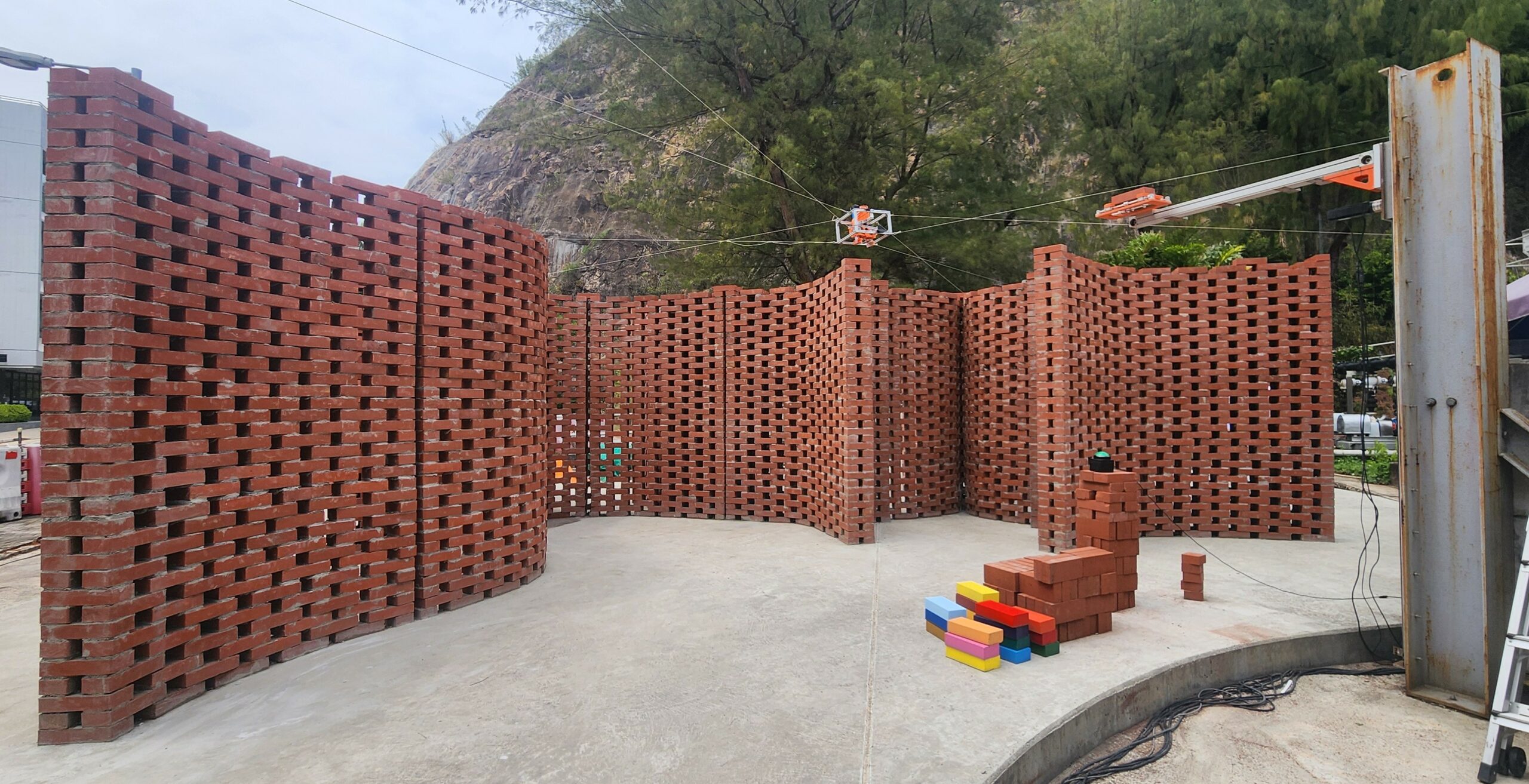

Skyscrapers are now a common sight, while brick-built buildings have become increasingly rare. This is because constructing with bricks is inherently more complex, requiring hands-on construction with specialised workers. Using bricks enables architects to design highly intricate structures that can achieve dazzling aesthetic effects and adapt to challenging environments, such as the undulating terrain often found in places like Hong Kong. However, this beauty and flexibility come at a cost – both in terms of time and money. Brick construction is not particularly efficient, which tends to lengthen project timelines and inflate labour costs, something that developers are keen to avoid in an era that prioritises construction efficiency.

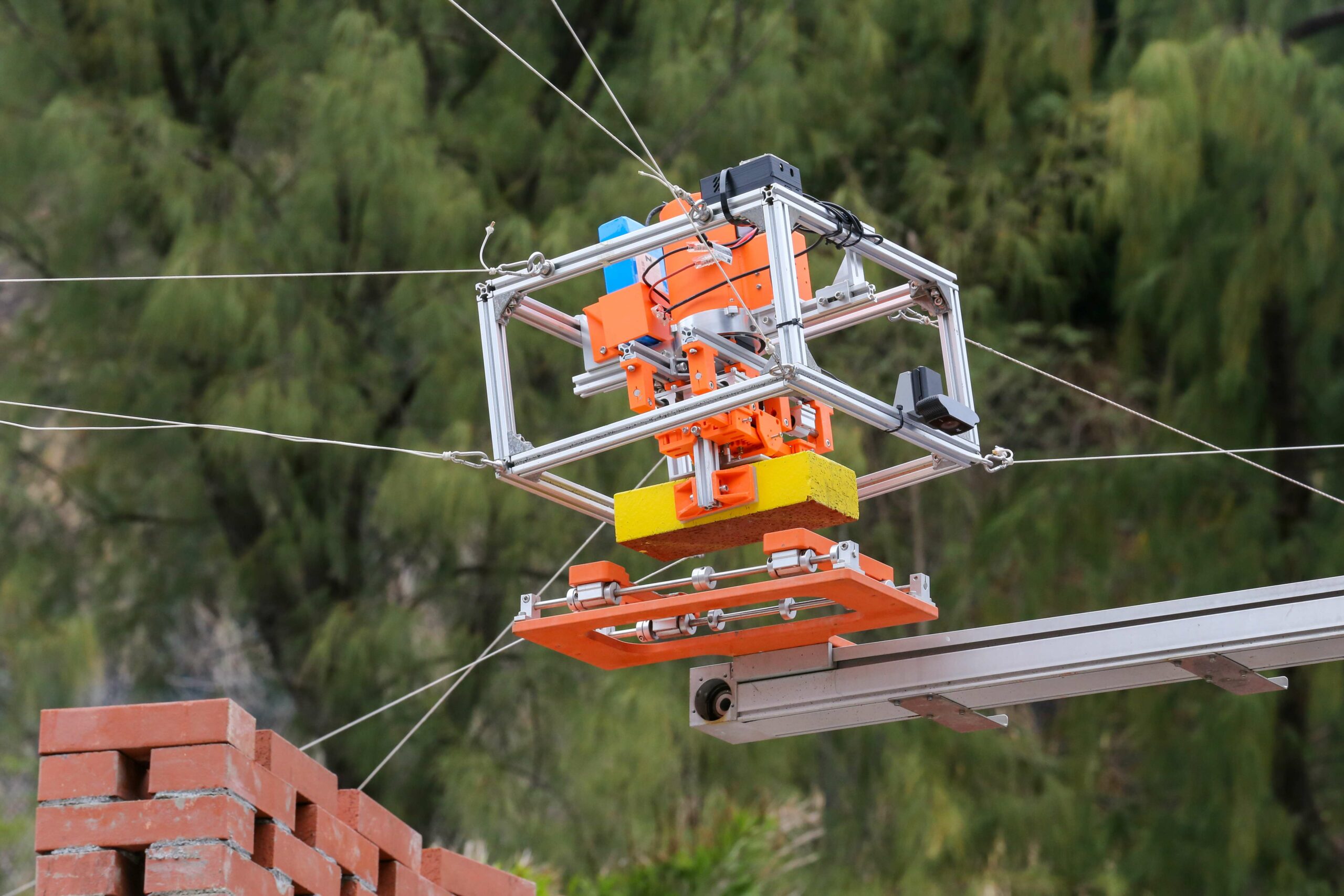

This challenge inspired a multidisciplinary team from CUHK to create CU-Brick, an innovative cable-driven robotic system with the potential to automate the construction process. The main components of the system include computational design tools that produce design solutions for the brick structure, the amount and location of the bricks and the sequence in which the structure is built; a robot driven by eight cables, connected to four support poles with motorised winches; and a gripper that accurately moves the bricks.

This system allows for tasks that were previously extremely difficult. While complex construction projects call for pinpoint accuracy from human workers and, as a result, mean that assembly takes a long time and can quickly get expensive, the robot doesn’t care whether the structure is complex or simple – in fact, it doesn’t even know the difference.

“The system allows architects to design complex structures without worrying about the challenges human workers might face in terms of efficiency and accuracy,” says Professor Darwin Lau Tat-ming, Associate Professor in the Department of Mechanical and Automation Engineering and the developer of CU-Brick. “The latter is particularly important to maintain the stability of complex structures.”

Where engineering meets artistry: the CU-Brick system

Computational design is an established field within architecture, but it mostly involves off-the-shelf robotics rather than tools custom-made for the job. The CU-Brick system builds on existing research in cable-driven robots and architectural design automation, but it’s never been consolidated into a holistic solution before.

“This project is novel, as it allows us to use bespoke robotic tools – control systems – in all the ways that a heavy robotic arm cannot be used,” says Adam Fingrut, Senior Lecturer from the School of Architecture and CU-Brick research partner. “Pick-and-place activities, precisely moving material around on a project site, for example, are not typical in architecture – but with the CU-Brick system, we could begin exploring those possibilities, linking design, robotics, structural engineering and others to our work.”

Architectural proposals can be developed using CU-Brick system based on the specific needs of an individual project. We turn them into a collection of data representing design details, location, orientation, material type and order of operations for safe assembly. This is all saved into a basic text file, based on an agreed common data language and then shared with the robotics team for automatic assembly.

“Using programming languages to directly communicate with construction technology on a project site is extremely innovative,” says Adam Fingrut. “It allows us as architects to rethink the role of traditional architectural drawings – plans and sections – replacing them with data communicated directly to construction robotics.”

This way of working opens up all sorts of new possibilities. “I was excited at the prospect of working with robotic engineers to develop a new system for creating architectural outcomes. Traditionally, architects don’t get to work directly with robotics and mechanical engineering. However, in this instance, we could collaborate on a research question and explore possibilities of practical design and system development towards a positive, achievable outcome.”

From campus showcase to industry transformation

The potential of CU-Brick has already been vividly demonstrated within the CUHK campus itself. The Yard for Environmental Sustainability (YES), which is due to open in June this year, was constructed using the technology. A collaboration which serves as a proof of concept, potentially paving the way for all sorts of other projects that involve automation, digitisation and robotic construction labour.

The technology is promising and has received very positive feedback from industry professionals and relevant organisations. However, Professor Lau notes that there are still quite a few challenges left to overcome: how to automatically apply mortar and other bonding materials; how to ensure the system can replicate human craftsmanship; and how to work with regulators to meet all their requirements. Once those issues are straightened out, get ready for a future where CU-Brick is used in the real world – and buildings are constructed by the equivalent of robots in hard hats.